ORIGINAL ARTICLES

Simple methods to decrease sodium and nitrite contents in hams

Procesos simples que disminuyen el contenido de sodio y nitritos en jamones

Talia Franco–Avila a; Irinea Yañez–Sánchezb; Adriana Paola Avila–Guerrero a; Cynthia Teresa Madera–Ibarraa ; Luis Gerardo Navarro–Gómeza ; Francisco Javier Gálvez–Gastéluma,c,*

a Centro Universitario de Ciencias de la Salud, Universidad de Guadalajara, Guadalajara, Jalisco, México.

b Centro Universitario de los Valles, Universidad de Guadalajara, Jalisco, México.

c Laboratorio de Patología, Dpto. de Microbiología y Patología, Centro Universitario de Ciencias de la Salud, Universidad de Guadalajara, Guadalajara, Jalisco, México.

Received: 09/12/2014

Accepted: 02/06/2015.

CITA

Franco–Avila T, Yañez–Sánchez I, Avila–Guerrero AP, Madera–Ibarra CT, Navarro–Gómez LG, Gálvez–Gastélum FJ. Simple methods to decrease sodium and nitrite contents in hams. Rev Esp Nutr Hum Diet. 2015; 19(2): 77 – 89. DOI: 10.14306/renhyd.19.2.140

ABSTRACT

Introduction: Ham is a product highly consumed by society; however it contains some elements that make it a non–recommended food. Thus, it has been attempted to eliminate or reduce those components.

Material and Methods: Content of sodium, nitrites, peroxides and total coliforms were compared after processes of Washing (W) and Simple Cooking (SC) in turkey and pork ham in a cross–sectional analytical experimental study. Furthermore, sensory acceptance of the samples through an acceptance test of five points was evaluated. One–way ANOVA with post hoc Bonferroni were used to assess the mean difference between groups. The value of p≤0.05 was considered statistically significant.

Results: Both processes reduced the amount of sodium in both types of ham in statistically significant way (p≤0.001). The major percentage of reduction was presented with SC: 73.4% for turkey ham and 63.5% for pork ham. Likewise, the higher percentage of nitrite reduction was 50.6% in pork ham with SC technique (p≤0.05). Peroxide index decreased with both techniques in both hams without statistical significance. Total coliforms count was kept constant in all samples. Higher sensory acceptance of W concerning SC in all sensory characteristics was observed.

Conclusions: W and SC techniques reduce sodium, nitrite and peroxide index without affecting the sanitation of hams. Furthermore, W is accepted in all sensory categories. We recommend using W technique before consumption of the product.

Keywords: Sodium Dietary; Nitrites; Food; Ham; Sensory Evaluation; Peroxides; Peroxide Index; Total Coliforms.

RESUMEN

Introducción: El jamón, producto altamente consumido por la sociedad, contiene algunos elementos que lo convierten en un alimento no recomendable, por lo que se ha buscado eliminar o reducir esos componentes.

Material y Métodos: Se compararon los contenidos de sodio, nitritos, índice de peróxidos y coliformes totales resultantes de los procesos de Lavado (L) y Cocción Simple (CS) aplicados al jamón de pavo y de cerdo en un estudio transversal analítico experimental. Además, se evaluó la aceptación sensorial de las muestras a través de una prueba de aceptación de cinco puntos. Se aplicó la prueba ANOVA de 1 vía con post hoc de Bonferroni para valorar la diferencia de medias entre grupos. El valor de p≤0,05 se consideró estadísticamente significativo.

Resultados: Ambos procesos redujeron la cantidad de sodio en ambos tipos de jamón de manera estadísticamente significativa (p≤0,001). El mayor porcentaje de reducción se presentó con CS: 73,4% para el jamón de pavo y 63,5% para el jamón de cerdo. Asimismo, el mayor porcentaje de reducción de nitritos fue de 50,6% con la técnica de CS en el jamón de cerdo (p≤0,05). El índice de peróxidos disminuyó con ambas técnicas en ambos jamones sin significancia estadística. El conteo de coliformes totales se mantuvo constante en todas las muestras. Se observó una mayor aceptación sensorial de L sobre CS en todas las características sensoriales.

Conclusiones: Las técnicas de L y CS reducen sodio, nitritos e índice de peróxidos sin afectar la sanidad de los jamones. Asimismo, L es aceptada sensorialmente en todas sus categorías. Se recomienda utilizar la técnica de L antes del consumo del producto.

Palabras clave: Sodio Dietético; Nitritos; Alimento; Jamón; Evaluación Sensorial; Peróxidos; Índice de Peróxidos; Coliformes Totales.

INTRODUCTION

Ham is a processed meat product widely used in our diet. Due to the considerable perishability of this product, it is usually labelled with 3 months as a maximum consumption period1,2. In its development, hams are exposed to various processes such as curing, where salts such as sodium chloride (NaCl), nitrites, nitrates, and other food additives are added in order to preserve the sanity of the product3.

Curing is an activity developed from ancient times. Prior to development of cold–preservation control (refrigeration), the deterioration of meat products was stopped effectively using NaCl as the principal agent. Today, meat and poultry industry have been benefited from the use of sodium nitrite (NaNO2) by allowing the production of meats with improved food safety and extended shelf–life with excellent storage stability4.

At certain level, sodium nitrite prevents the growth of some types of bacteria that are responsible from meat alteration (Clostridium and Listeria monocytogenes genus mainly)5,6,7 and provides desirable organoleptic characteristics of meat products as pink color, taste, stability against lipid oxidation, enrichment of the texture and special flavor1,6,8.

Around 80% of sodium intake comes from processed food and 7% comes from processed meats9,10. In hams the amount of sodium is usually from 1500 to 1800 milligrams (mg) per 100 grams (g) of product11 in contrast with the Recommended Daily Intake (RDI) which recommends a maximum intake of sodium from 1000 to 1500mg12. Otherwise, the quantity of nitrite allowed in meat products is 15.6mg per 100g13 and the Joint Committee of Food and Agriculture Organization–World Health Organization (FAOWHO) establishes the Acceptable Daily Intake (ADI) of less than 0.09mg of sodium nitrite per kilogram (kg) of body weight14. Thus, an adult with 60kg of body weight could get an amount of 5.4mg of residual nitrite but it is permitted to have a quantity of 15.6mg per 100 of meat product. This would be more than double of the total allowed by FAOWHO15.

The use of sodium nitrite on curing is in controversy. The excessive sodium and nitrite intake is related to some diseases as high blood pressure, obesity16,17, renal disease18,19, methemoglobinemia and impaired lung function20–23. Furthermore nitroso compounds could contribute to nitrosamine formation24. Nitrosamines are chemicals with toxic, mutagenic and carcinogenic potential effects25,26. It is believed that nitrosamines are formed due to residual nitrites existed in cured meat products and it has found higher levels than the permitted in these products27. It is important to know that the level of nitrosamines tolerated for humans is from 5 to 10 micrograms (µg) per kg of body weight21 (Figure 1).

In recent years the interest on Spanish cured ham has increase in México. In 2012, with 82.7 of tons exported to México, it became the fifth destination of Spanish cured ham exports and the largest market in Latin America. However, local consumption in México of other meats as ham and sausages remains much higher28.

Because of this problem, some industries have done many studies trying to reduce the sodium and nitrite amount during sausages preparation; however organoleptic characteristics have been affected15,29,30. Other researchers have used substitutes of salt with moderately positive results31. However, reduction assays of sodium and nitrites at time of consumption subsequent to marketing were not found. This could increase the acceptance of the product and could decrease microbiological risk. Thereby, the aim of this study is explore alternatives of sodium and nitrite reduction in turkey and pork ham and its impact on microbiological and organoleptic characteristics.

MATERIAL AND METHODS

Study design

The present study is cross–sectional analytical experimental. Two brands of turkey ham were selected along with two brands of pork ham by non–intentional probabilistic method. The selection method was according to the criteria established by a study performed by the ''Procuraduría Federal del Consumidor'' in México (PROFECO), amongst the criteria we can find frequent consumption, good quality and standardized packaging. Thus, it was decided to choose turkey ham with added soy and an average of 14% of protein and pork ham with added soy and an average of 16% protein32. Characteristics of the selected brands can be found on Table 1.

Procedures

Techniques were chosen based on previous studies that showed reduction of similar elements to sodium and nitrites, such as Washing (W) and Simple Cooking (SC) techniques. W technique consists of exposing the ham sample to a constant water drop at ambient temperature (20°C approximately) for 1 minute with rubbing of hands. SC technique consists of submerging the ham sample into 1 liter of water, heat it up to boiling point and remove from fire18,33. All the samples were dried and cooled at ambient temperature. Subsequently, they were homogenized to a net content of 150g of product per determination per sample. Sodium, sodium nitrite, peroxide index and total coliforms determinations were done in a maximum of 24 hours after the techniques were applied.

Sodium and nitrite determination

Sodium determination was performed using the Flame Atomic Absorption Spectrometry method following the procedures indicated in NOM–117–SSA1–1994 and NOM– 086–SSA1–199434,35. We proceed to calibrate the equipment and to create the calibration standards, concentration of the calibration standards were between the dynamic sodium concentration intervals. Based on the absorption obtained, calculations were made to represent sodium content in mg/100g of sample.

For NaNO2 quantification, the method validated on NMX–F–543–199236 was followed and the calibration curve for curated products was made. The results were represented in mg/kg per sample. These results were calculated based on the absorbency registered by the spectrophotometer at 520 nm (nanometers) adjusting zero with the blank (B).

Lipid peroxidation and microbiological evaluation

Peroxide Index evaluation was made using the titulometric procedure validated on NMX–F–614–NORMEX–200437. The content of substances that oxidize potassium iodide was estimated and was represented in milliequivalents of active oxygen per kg of sample (meqO2/kg). Peroxide Index is associated with the presence of peroxides of fatty acids presents in the sample.

Sample preparation to determine total coliforms was made according to the NOM–110–SSA1–199438. The analysis of total coliforms presence was made through the count in plaque technique, validated on NOM–113–SSA1–199439. The number of total coliforms was quantified using a selective culture medium where bacteria was developed at 35°C, resulting in gas and organic acids production which turned the pH indicator and precipitated bile salts. The results were presented in Colony–forming units per gram (CFU/g).

Organoleptic analysis

Sensory acceptance of the samples was also evaluated. In order to do this, an acceptance test of five points was used: ''Like very much'', ''Like'', ''Don't like/dislike'', ''Dislike'', ''Dislike very much''. Twenty four persons between 19 and 23 years old were selected with non–probabilistic intentional method. They assessed the texture, odor, flavor and color of the different process applied to hams. Furthermore, results of sodium reduction of each type of ham were grouped according to NOM–086–SSA1–199435 in the following way: ''Sodium free ham'' if it contains ≤5mg/60g of product, ''Very low sodium ham'' if it contains ≤35mg/60g of product, ''Low sodium ham'' if contains ≤140mg/60g of product and ''Reduced sodium ham'' if it contains ≤25% than the original ham. NOM–086–SSA1–1994 establishes the nutritional specifications that modified foods (reduced, eliminated or added foods) have to keep.

In addition, it was carried out a sensory perception evaluation at the same subjects with a consumer panel survey40. They evaluated the following characteristics:

• Texture: fibrous, juicy and tender.

• Taste: extremely salty, salty, sweet, bitter and metallic.

• Color: faint pink, marble pink, bright pink and uniform color.

• Odor: smoky, sweet, salty and metallic.

Statistical analysis

Data analysis was performed in edition 20 SPSS software. Parametric variables are presented in means and standard deviation and qualitative variables in frequency and percentage. The content of sodium, sodium nitrite, peroxide index and total coliforms of the blank and the different techniques were compared through One–way ANOVA test and post hoc Bonferroni test. Value of p≤0.05 was considered statistically significant.

RESULTS

Sodium and nitrite

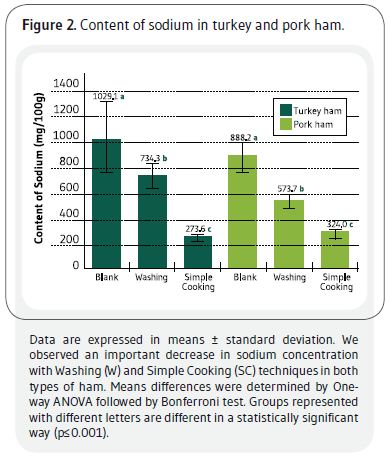

W and SC processes reduced the sodium content in both types of ham in statistically significant way (p≤0.001) (Figure 2). However, SC technique presented the main reduction of sodium in turkey ham (1029±244.9mg/100gB vs 273±27.7mg/100gSC) likewise in pork ham (888.2±80.3mg/100gB vs 324±21.6mg/100gSC). The percentage of reduction shown with SC technique was 73.4% for turkey ham and 63.5% for pork ham.

Regarding to NaNO2 quantification, both processes decrease this compound (Figure 3). For turkey ham, the most important reduction was shown with SC (122.7±51.1mg/kgB vs 51.0±14.9mg/kgSC) this was equivalent to 58.4% of reduction, however it was not considered statistically significant. Otherwise, pork ham showed significant decrease of NaNO2 with both processes (p<0.05). The higher percentage of reduction was 50.6% with SC technique (109.5±16.3 mg/kgB vs 54.1± 4.6mg/kgSC).

Lipid peroxidation and total coliforms

Both processes reduced peroxide index (Table 2). The major depletion of peroxide index in turkey ham was shown with SC method (66.7% of reduction). Besides, the higher depletion of peroxide index in pork ham was shown with W technique (63.1% of reduction). Both results were considered statistically significant (p≤0.05).

In regard to total coliforms, there were not significant differences between B, W and SC processes, this is due to all the samples showed a total coliform count of <10CFU/g with exception of one blank pork sample that had a count of 20CFU/g (Table 2).

Organoleptic analysis

Results of organoleptic analysis are described in Figures 4 and 5. In general, W technique was more accepted than SC technique. SC technique primarily affected texture and taste in both types of ham due to nearly 50% of the respondents reported that they ''Dislike very much'' these characteristics. However color and odor characteristics were reported indifferent due to approximate 30% of the respondents reported that they ''Don't like/dislike''. In another way, W technique was located in ''Like'' category in all the organoleptic characteristics according to 30–40% of the respondents.

W and SC processes reduced sodium in 28.6% and 73.4% respectively in turkey ham, placing them into ''Reduced sodium ham'' category. The same processes reduced in 35.4% and 63.5% respectively in pork ham, placing them into ''Reduced sodium ham'' category. This is according to NOM–086–SSA1–199435.

Regarding to sensory perception, in general there is not differences between blank and W and SC techniques (Figures 6 and 7). Texture and taste perception were the most affected due to the percentages are different. However, percentages of color and odor are very similar.

DISCUSSION AND CONCLUSIONS

Meat consumption has increased during the last years. From a physiological perspective, rich meat diets have several nutritional benefits but also some potential adverse effects; this could impact in chronic disease development and finally death. The 2005 US Dietary Guidelines for Americans recommends moderated consumption of red and processed meat41. Such recommendations are due to high content of cholesterol and saturated fatty acids of these products have been shown to be positively associated with increased Low Density Lipoprotein concentrations (LDL) and major risk of Coronary Heart Disease (CHD), stroke, and type 2 diabetes mellitus42,43.

Sodium salts, sodium nitrite and sodium nitrate are components authorized for it use in several foodstuffs such as non–heat–treated, cured and dried meat products. The objective of preservatives use as nitrates and nitrites is to find a balance between ensuring the microbiological safety and keeping the level of nitrosamines as low as possible and to improve several organoleptic characteristics as color and flavor. Moreover, nitrate reduction to nitrite is important in controlling lipid oxidation process during the ham ripening and it is essential in the development of the characteristic cured flavor44.

Sodium chloride plays an important role in flavoring and preservation. Furthermore sodium chloride decreases water activity in meat products influencing its shelf life45–47.

Similarly, sodium nitrite is essential in meat industry due to it improves safety and sets the characteristic color of smoked and cured meats21,48.

Sodium intake exceeds nutritional recommendations mainly in industrialized countries. It has implications in elevated blood pressure, development of hypertension and positive association with mortality and CHD risk. Given this, it has promoted recommendation programs to reduce the intake of sodium without conclusive results49. On the other hand, nitrite represents another risk to the health of consumers. The nitrite itself is rather toxic in comparison to nitrate. As a rule, nitrite is 10 times more toxic than nitrate. The lethal oral doses for human beings are 80–800mg of nitrate/kg of body weight and 33–250 mg of nitrite/kg of body weight44. Nitrites are absorbed by diffusion through gastric mucosa and gut wall, it reacts with hemoglobin and could cause methemoglobinemia, decreased oxidative phosphorylation, inhibition of microsomal enzymes and other toxic effects which could eventually cause death20,21,48. Several studies indicated that frequent consumption of meat with high levels of nitrite is related to obstructive lung function by nitrosative stress generation15,22. Furthermore, reaction of nitrites with amines could cause the formation of N–nitroso compounds such as nitrosamines, highly reactive and responsible of causing embryopathy mutagenic effects. Children are especially susceptible to these effects due to their low body weight, immature enzyme system and weakness in gastric system21,50.

According to NOM–086–SSA1–1994, the consumption of 60g of ham covers more than one third of the RDI of sodium for an adult. It represents 37% of RDI in turkey ham and 34% of RDI in pork ham35. This percentage could decrease with the process applied in this research: 60g of turkey ham could contain only 10.9% of the RDI if SC technique is applied and pork ham could contain 0.9% of the RDI with the same technique.

One finding of this research is the difference found in the concentrations of sodium and nitrites between turkey and pork ham. Sodium and nitrite concentration was higher in turkey ham against pork ham (1029.1mg and 888.2mg in the case of sodium and 122.7mg/kg and 109.5mg/kg in the case of nitrites respectively). The above information becomes relevant because it could influence the choice of meat product based on the health of the consumer.

Nowadays there are not recommendations scientifically validated to processes sausages in home in order to reduce concentrations of sodium and nitrite. However, Burrowes et al. conducted a similar study in which they reduced potassium in some potato varieties. Results revealed that SC and Double Cocking processes (DC) decreased significantly this mineral38. Other experimental alternatives have been performed to reduce sodium concentration during product development, as reported by Stopfoth et al. They used potassium lactate on the formulation, decreasing 42% of the sodium content51. Lavieri et al. used nitrites of plant origin in combination with high hydrostatic pressure with the objective to inhibit L. monocytogenes growing having favorable results7. The same author has worked with other natural or organic methods with promising results52. One of these methods is natural vegetable juice, which has proved quality and usefulness comparable with conventional curing methods53. Meat products with organic or natural additives without nitrites or nitrates are good alternative of consumption54. However several low–sodium meats obtained by physical and chemical methods have failed in sanity quality, sensory perception and consumer acceptance52. Thus simple methods applied at the time of consumption could become an economic and acceptable alternative. In our study SC reduced more quantity of sodium in turkey and pork ham with 73.4% and 63.5% respectively, and nitrites with 58.4% and 50.6% respectively.

The oxidative rancidity is delayed by nitrites in cured meats by four different mechanisms proposed: by reaction of nitrites with heme pigments forming a stable complex, for its action in tissue membranes by stabilizing its unsaturated lipids, by action of nitrite as a metal chelate and finally by the formation of N–nitroso compounds that could act as radical scavengers5.

The oxidative decomposition of lipids (lipid oxidation) and amino acids degradation have been reported to produce a high variety of compounds, as aldehydes and esters that have shown to be contributors to the loss of desirable flavor in meats. In addition, these aldehydes are important contributors to the aroma in meats5. Our results demonstrated mild effects of SC process in peroxides contents respect to W and B.

On the other hand, the addition of nitrates and nitrites to cured ham reinforces the preserving effect of salting by inhibiting the growth of bacteria1. We demonstrate that W and SC processes don't increase the sanity risk of the product, as evidenced by the analysis of total coliforms. Microbial analysis of the processed ham indicated no significant differences in aerobic plate count.

Respect to organoleptic properties, we found that the process in which heat is applied and therefore which reduced sodium and nitrites significantly (SC) were the least accepted sensory. In contrast, those in which heat were not applied were mostly accepted (W). Rejection of low sodium technics is due to the use of sodium and nitrites are essential to improve sensory characteristics as well as they are important agents emulsifiers, flavor enhancers, color enhancers, water and fat binder and microorganisms controller8.

It is important to know that determination methods used in the study are validated and they are included in national norms3,18,33–40. Further, analyses were performed integrally including sodium quantity, nitrite quantity, lipid peroxidation index, microbiological evaluation and organoleptic characteristics. We obtained a statistical significance of p≤0.001 in reducing sodium in both hams. Nitrites content was affected by simple methods and SC obtained a statistical significance of p≤0.05 in reducing nitrites in pork ham.

More researches in other type of sausages are needed. It is necessary to analyze the loss of water–soluble nutrients, to determine changes in fat content in the product after applying reduction process. In addition to this, it is important to investigate whether the interaction of nitrite during cooking generates N–nitroso components such as nitrosamines and their effects in experimental models.

ACKNOWLEDGEMENTS

We appreciate the work of the researches: Tania Salinas Polanco, Maritza Paredes Gutiérrez, Lizbeth Rodríguez Ponce, Mariana Rosas Ramos, Patricia Salcedo Parra and Saúl Gallegos Castillo for their groundwork, in which this research is based.

COMPETING INTERESTS

The authors state that there are no conflicts of interest in preparing the manuscript.

BIBLIOGRAPHY

1. Ferreira IM, Silva S. Quantification of residual nitrite and nitrate in ham by reverse–phase high performance liquid chromatography/diode array detector. Talanta. 2008; 74(5): 1598–1602.

2. Totosaus A. Productos cárnicos emulsionados bajos en grasa y sodio. Nacameh. 2007; 1: 53–66.

3. Norma Oficial Mexicana 213 (NOM–213–SSA1–2002), Productos y servicios, Productos cárnicos procesados, Especificaciones sanitarias, Métodos de prueba.

4. Pegg RB, Shahidi F. Nitrite curing of meat. Wiley–Blackwell, Ames, Iowa, USA. 2000.

5. Toldrá F, Aristoy MC, Flores M. Relevance of nitrate and nitrite in dry–cured ham and their effects on aroma development. Aceites y Grasas. 2009; 60(3): 291–96.

6. Epley RJ, Addis PB, Warthesen JJ. Nitrite in Meat. St. Paul, MN: University of Minnesota Extension Service. Retrieved from the University of Minnesota Digital Conservancy; [updated Jan 11, 1992; accesed April 15, 2015]. Available in: http://conservancy.umn.edu/handle/11299/50792

7. Lavieri NA, Sebranek JG, Cordray JC, Dickson JS, Horsch AM, Jung S, et al. Effects of different nitrite concentrations from a vegetable source with and without high hydrostatic pressure on the recovery of Listeria monocytogenes on ready–to–eat restructured ham. J Food Prot. 2014; 77(5): 781–87.

8. Ruusunen M, Puolanne E. Reducing sodium intake from meat products. Meat Sci. 2005; 70(3): 531–41.

9. Dietary Guidelines Advisory Committee. Report of the dietary guidelines advisory committee on the dietary guidelines for Americans to the secretary of agriculture and the secretary of health and human services.Washington, D.C.: U.S. Dept. of Agriculture, Agricultural Research Service; 2010.

10. Agence Française de Sécurité Sanitaire des Aliments. Rapport du groupe de travail sur le sel. Paris, France; 2002.

11. Reguerio G. Situación del jamón curado en las tendencias nutricionales actuales (transición nutricional). Cárnicas. 2000; 270: 36–41.

12. United States Department of Agriculture. DRI Tables. United States of America: Food and Nutrition Information Center; [updated Sep 13, 2011; accesed April 15, 2015]. Available in: http://fnic.nal.usda.gov/nal_display/index.php?info_center=4tax_level=3tax_subject=256topic_id=1342level3_id=5140

13. Norma Oficial Mexicana 145 (NOM–145–SSA1–1995), Productos cárnicos troceados y curados, Productos cárnicos curados y madurados, Disposiciones y especificaciones sanitarias.

14. FAO/WHO. Toxicological evaluation of certain food additives and contaminants. Nitrite. Ginebra, 1996:269–323 / (WHO Food Additives Series; No. 35).

15. Matilus RJ, Floyd KMC, Sutherland JW, Brewer MS. Sensory characteristics of frankfurters as affected by salt, fat, soy protein and carrageenan. J Food Sci. 1995; 60: 48–54.

16. Haro MI. Consumo de fibra dietética, sodio, potasio y calcio y su relación con la presión arterial en hombres adultos normotensos. Salud Pública de México. 1998; 40: 241–47.

17. Doaei S, Gholamalizadeh M. The association of genetic variations with sensitivity of blood pressure to dietary salt: A narrative literature review. ARYA Atheroscler. 2014; 10(3): 169–74.

18. Mahan LK, Escott–Stump S. Nutrición y dietoterapia de Krause. 10.a ed. Mahan LK, Escott–Stump S, editores. México: McGraw– Hill Interamericana; 2001.

19. Magden K, Hur E, Yildiz G, Kose SB, Bicak S, Yildirim I, et al. The effects of strict salt control on blood pressure and cardiac condition in end–stage renal disease: prospective–study. Ren Fail. 2013; 35(10): 1344–47.

20. Evangelista M, Prada DB, Digón A, Ezpeleta DC, Giunípero G, Piola JC. Brote de intoxicación con nitrito de sodio asociado a manejo inadecuado de residuos sólidos en Rosario, Argentina, 2003. Rev Méd Rosario. 2006; 72: 67–72.

21. Ruiz FJ, Isaac LM, Prometa DMA, García RMO. Caracterización del riesgo de nitrito de sodio mediante la estimación de la ingestión diaria máxima teórica y la ingestión diaria efectiva por estudiantes del municipio de Santiago de Cuba. Reporte Técnico de Vigilancia. 2007; 12: 1–9.

22. Jiang R.D, Paikavid C, Hankinson JL, Graham BR. Cured meat consumption, lung function, and chronic obstructive pulmonary disease among United States adults. Am J Respir Crit Care Med. 2007; 175: 798–804.

23. Vollmer G, Josst G, Schenker D, Sturm W, Vreden N. Elementos de bromatología descriptiva. 1.a ed. Vollmer G, editor. Zaragoza, España: Acribia; 1999.

24. Sindelar JJ, Milkowski AL. Sodium Nitrite in Processed Meat and Poultry Meats: A Review of Curing and Examining the Risk/Benefit of Its Use. American Meat Science Asoociation. White Paper Series. 2011; 3: 1–14.

25. Rywotycki R. The effect of selected functional additives and heat treatment on nitrosamine content in pasteurized pork ham. Meat Sci. 2002; 60(4): 335–39.

26. Cassens RG. Composition and safety of cured meats in the USA. Food Chem. 1997; 59(4): 561–66. 27. Avasilcăi L, Cuciureanu R. Nitrates and nitrites in meat products–nitrosamines precursors. Rev Med Chir Soc Med Nat Iasi. 2011; 115(2): 606–11.

28. Oficina Económica y Comercial de la Embajada de España en México. El mercado del jamón y el embutido curado en México. España Exportación e inversiones; [updated Jun 13, 2013; accesed April 15, 2015]. Available in: http://internacional.ivace.es/dms/estudios/informacion_paises/MXICOJAMONEBUTIDOICEX2013-/M%C3%89XICOJAMONEMBUTIDOICEX2013%20.pdf

29. Aliño M, Grau R, Toldrá F, Barat JM. Physicochemical changes in dry–cured hams salted with potassium, calcium and magnesium chloride as a partial replacement for sodium chloride. Meat Sci. 2010; 86: 331–36.

30. Bertram HC, Wu Z, Straadt IK, Aagaard M, Aaslyng MD. Effects of pressurization on structure, water distribution, and sensory attributes of cured ham: can pressurization reduce the crucial sodium content? J Agric Food Chem. 2006; 54: 9912–17.

31. Pietrasik Z, Gaudette NJ. The impact of salt replacers and flavor enhancer on the processing characteristics and consumer acceptance of restructured cooked hams. Meat Sci. 2014; 96(3): 1165–70.

32. Procuraduría Federal del Consumidor. Calidad de jamones. Revista del consumidor. México: PROFECO. 2001; 289: 1–9.

33. Burrowes JD, Ramer NJ. Changes in potassium content of different potato varieties after cooking. J Renal Nutr. 2008; 18: 530–34.

34. Norma Oficial Mexicana. NOM–117–SSA1–1994. Bienes y servicios. Método de prueba para la determinación de cadmio, arsénico, plomo, estaño, cobre, fierro, zinc y mercurio en alimentos, agua potable y agua purificada por espectrometría de absorción atómica.

35. Norma Oficial Mexicana. NOM–086–SSA1–1994. Bienes y servicios. Alimentos y bebidas no alcohólicas con modificaciones en su composición. Especificaciones nutrimentales.

36. Normas Mexicanas. Dirección General de Normas. NMX–F–543–1992. Foods. Test method for nitrites determination in meat products.

37. Normas Mexicanas. Dirección General de Normas. NMX–F– 614–NORMEX–2004. Alimentos. Determinación del índice de peróxidos en alimentos (método titulométrico).

38. Norma Oficial Mexicana. NOM–110–SSA1–1994. Bienes y servicios. Preparación y dilución de muestras de alimentos para su análisis microbiológico.

39. Norma Oficial Mexicana. NOM–113–SSA1–1994. Bienes y servicios. Método para la cuenta de microorganismos coliformes totales en placa.

40. Frontela C, López G, Ros G, Martínez C. Relación entre los parámetros sensoriales, físicoquímicos e instrumentales en el jamón cocido. An Vet (Murcia). 2006; 22: 67–78.

41. Adams SM, Standridge JB. What should we eat? Evidence from observational studies. Southern Medical Journal. 2006; 99: 744–48.

42. Mozaffarian D, Micha R, Wallace S. Effects on coronary heart disease of increasing polyunsaturated fat in place of saturated fat: a systematic review and meta–analysis of randomized controlled trials. PLoS Med. 2010; DOI: 10.1371/journal.pmed.1000252.

43. Renata Micha, Sarah K, Wallace BA, Dariush Mozaffarian. Red and processed meat consumption and risk of incident coronary heart disease, stroke and diabetes mellitus. Circulation. 2010; 121: 2271–83.

44. Schuddeboon LJ. Nitrates and nitrites in foodstuffs. Counsil of Europe Press, 1993.

45. Ruusunen M, Sarkka–tIRKKONEN M and Puolanne E, Saltinness of coarsely ground cooked ham with reduced salt content. Agricultural and Food Science in Finland. 2001; 10: 27–32.

46. Stopforth JD, Kroon H, Sijtsema P, Visser D and Bontenbal EW, Effectively reducing sodium content, Fleischwirtschaft International. 2010; 3: 21–22.

47. Pietrasik Z and Gaudette NJ, The impact of salt replacers and flavor enhancer on the processing characteristics and consumer acceptance of restructured cooked hams, Meat Science, 2014; 96: 1165–70.

48. López VME. Nitrito de sodio en productos cárnicos elaborados en Cienfuegos. Revista Cubana Aliment Nutr. 2002; 16(1): 19– 22.

49. Webster JL, Dunford EK, Hawkes C, Neal BC. Salt reduction initiatives around the world. J Hypertens. 2011; 29(6): 1043– 50.

50. Sanches FPJ, Rios A, Valc!arcel M, Bastos CE. Development of a new method for the determination of nitrosamines by micellar electrokinetic capillary chromatography. Water Research. 2003; 37: 3837–42.

51. Lavieri NA, Sebranek JG, Brehm–Stecher BF, Cordray JC, Dickson JS, Horsch AM, et al. Investigating the control of Listeria monocytogenes on a ready–to–eat ham product using natural antimicrobial ingredients and postlethality interventions. Foodborne Pathog Dis. 2014; 11(6): 462–467.

52. Sindelar JJ, Cordray JC, Sebranek JG, Love JA, Ahn DU. Effects of varying levels of vegetable juice powder and incubation time on color, residual nitrate and nitrite, pigment, pH, and trained sensory attributes of ready–to–eat uncured ham. J Food Sci. 2007; 72(6): S388–S395.

53. Sebranek JG, Bacus JN. Cured meat products without direct addition of nitrate or nitrite: what are the issues? Meat Sci. 2007; 77: 136–47.

54. Vasilopoulos C, De Vuyst L, Leroy F. Shelf–life Reduction as an Emerging Problem in Cooked Hams Underlines the Need for Improved Preservation Strategies. Crit Rev Food Sci Nutr. 2015; 55(10): 1425–43.